Ancient records from across the Old World tell of a terrible disease. Among its symptoms, and indeed the symptom that gave the disease its name, was an excessive production of urine that was also markedly sweet1. Those afflicted with this disease would not have much longer to live, regardless of whether they contracted the disease at birth or later in adulthood2. The only way to avoid its consequences was a diet so limited as to be malnourishing3. The name of this fearsome affliction was … diabetes.

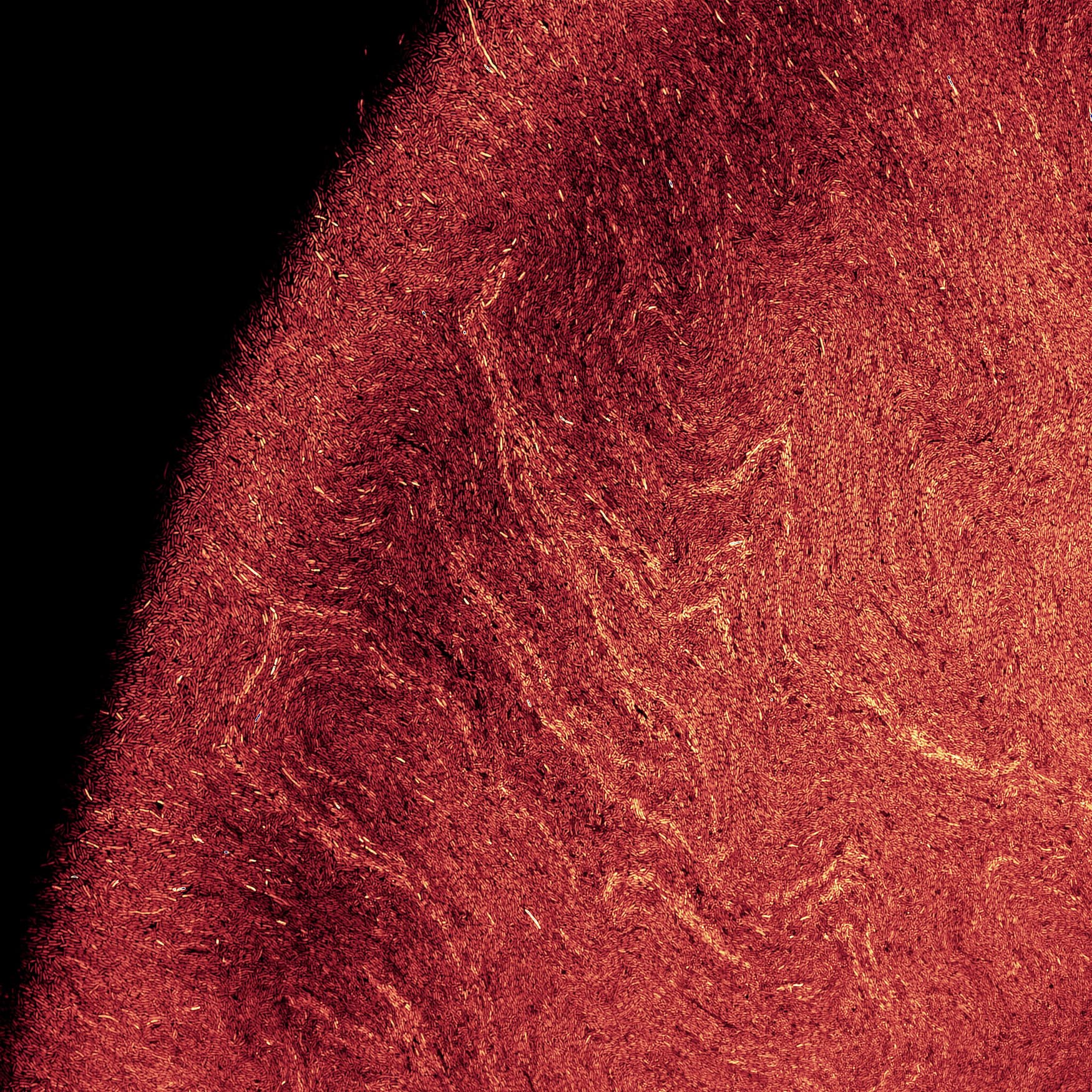

Diabetes was described in remarkable depth by the ancient Indian medical text called the Suśrutasaṃhitā, some leaves of which are shown here.

Credit: Los Angeles County Museum of Art. Public domain.

So what changed? How did a terrible and mysterious disorder turn into the butt of every joke about overly‐sweetened desserts? In a word: insulin. Medical insulin offered, for the first time ever, a reliable treatment for diabetes. Officially, its story begins with the discovery of isolated “islands” of cells in the pancreas, which would later be named the islets of Langerhans after the medical student who discovered them, and the later finding that diabetes seemed to be associated with a deterioration of the islets. In , a small team based in the University of Toronto announced the discovery of a hormone produced by these islets. The substance, christened “insulin” after the Latin word for island (insula), seemed to be intimately connected with diabetes — diabetic dogs could be kept alive for unexpectedly long when supplied with an intravenous insulin solution. But the solution was impure, and it did not work too well with human patients. After some bitter quarreling and drama, the team finally announced the discovery of pure insulin in , a medicine that actually appeared to work3.

But that’s not the main story I’d like to tell here. Even after the discovery of insulin, its manufacture was quite difficult. The discovery that would make it available to the masses was one that set the stage for a now‐burgeoning sector of the biomedical sciences. It was the production of insulin using bacteria.

Keiichi Itakura, working at UC Berkeley, had been part of a team that could create recombinant DNA — artificially-made DNA molecules that were just like the real thing, with the crucial difference being that researchers could create “custom” DNA sequences using this new technology. This was a big deal. In theory, people now had the ability to program cells with recombinant DNA to make all kinds of proteins to perform all kinds of functions. Right away, Itakura had the idea to make insulin, but that would have to wait. Insulin was a fairly complicated beast to try to make with the limited and untested technology of the time. Instead, he and another researcher, Arthur Riggs, set their sights on a different hormone, somatostatin4: xi, 29–30. It is in charge of inhibiting the release of various other hormones, including growth hormone and, yes, insulin5: Summary. The two planned to create some recombinant DNA coding for somatostatin which they would inject into the bacterium Escherichia coli. Not having the ability to know better, the bacterium would, in theory, dutifully churn out somatostatin. At first glance, this seemed like an ideal first step — somatostatin was small, easy for the bacterium to manufacture, and easily detectable even in small quantities4: 29–30. But it was still a daunting task, because proteins — or at least functional ones — made with recombinant DNA had not yet been created4: 33. The task was so daunting that government institutions simply would not fund it — they instead had to resort to a chance private partnership from a startup called Genentech4: 35. And by startup, I really do mean startup — the entire company was basically one guy’s lab4: 39.

But there was a problem: the somatostatin did not show up4: 40. It turned out that the bacteria were destroying the somatostatin fairly rapidly, and a tweak to the technique addressed this issue4: 42. Onwards the team went to insulin. It was an even more intimidating task than the first one, but, after many trials and tribulations, they had results.

Today, the basic technique of making bacteria perform labor is widely used. But perhaps we could take it further — a lot further.